Have a new design project and aren’t sure whether to use digital or offset printing? It’s not always easy to know which way to go. Every design project is different, so the answer varies from project to project. It isn’t just a matter of cost, there are many factors to be considered before choosing digital or offset for your printing needs. In order to make an educated decision, it is important to understand each method, as well as the advantages and disadvantages of each.

What is Digital Printing?

If you have a desktop printer at home, you’re familiar with process of digital printing. In digital printing, your electronic file is printed directly to the printing surface by the machine. There is no need for making films or plates, which results in a much more affordable print solution.

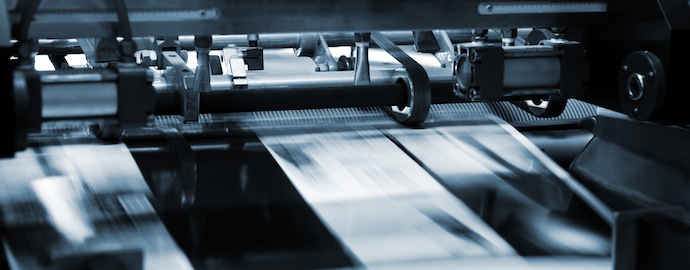

What is Offset Printing?

Offset printing is the most commonly trusted high volume commercial printing technology. In offset printing, the design image is first burned onto a plate, and is then transferred (or offset) from the plate to a rubber sheet, and finally to the printing surface. The lithographic process is based on the repulsion of oil and water. The image to be printed gets ink from ink rollers, while the non printing area attracts a film of water, keeping the non printing areas ink-free.

How to Decide?

Let’s take a look at some important factors to consider when choosing a print method:

- Quantity: Offset printing has a front-end cost load for plates and film, which means short runs (low quantities) may have a high per-unit cost. But as quantities increase, the unit cost goes down with offset printing. Very short runs can be more cost effective with digital printing; while larger quantities are likely to have a lower unit cost with offset printing.

- Turnaround: If you need it fast, digital usually offers quicker delivery than offset. The mechanical steps are eliminated in digital printing so there is no need to make films or plates as the image is printed directly to your chosen media.

- Size: Offset presses accommodate larger printed pieces, whereas digitally printed pieces have size and paper stock constraints.

- Color: If your print piece requires the use of the Pantone Matching System, offset printing will provide an accurate match. With digital printing, the Pantone color(s) cannot be matched exactly, but there is the ability to get rather close to desired colors. Digital presses use four-colour process (CMYK) printing. If you need only black ink or one or two ink colors, offset printing may offer a more cost-effective solution. If you need four-color printing, digital may offer advantages in lower up-front costs.

- Customization: Hands down, digital printing is the way to go with customized print pieces as offset printing does not allow for it. Digital print methods can print variable data on each individual piece, such as names or addresses without stopping or slowing down the process.

Pros and Cons of Digital and Offset Printing

Digital Printing

• Quick turnaround

• Cheap low volume printing

• Ability for customized pieces

• Accurate proofs

• Pantone (PMS) color matching not accurate

• Limited Size

Offset Printing

• Best for large quantity runs

• Best quality

• More choices as far as print materials and special effects

• Lower unit cost as quantity increases

• Accurate Pantone (PMS) color matching

• Larger format size pieces

• More time consuming / involved setup process

• Expensive proofing process

Summary

Ultimately, your choice of commercial printing process will depend on your quality and volume demands, budget and time schedule. In order to make the best decision, carefully list your requirements and compare the different processes based on your needs. You can also check out this cool infographic I found on digital vs offset printing for quick reference. And remember, we are always here to help so if you have a question or need a suggestion.

~ Bethany Howell, art director